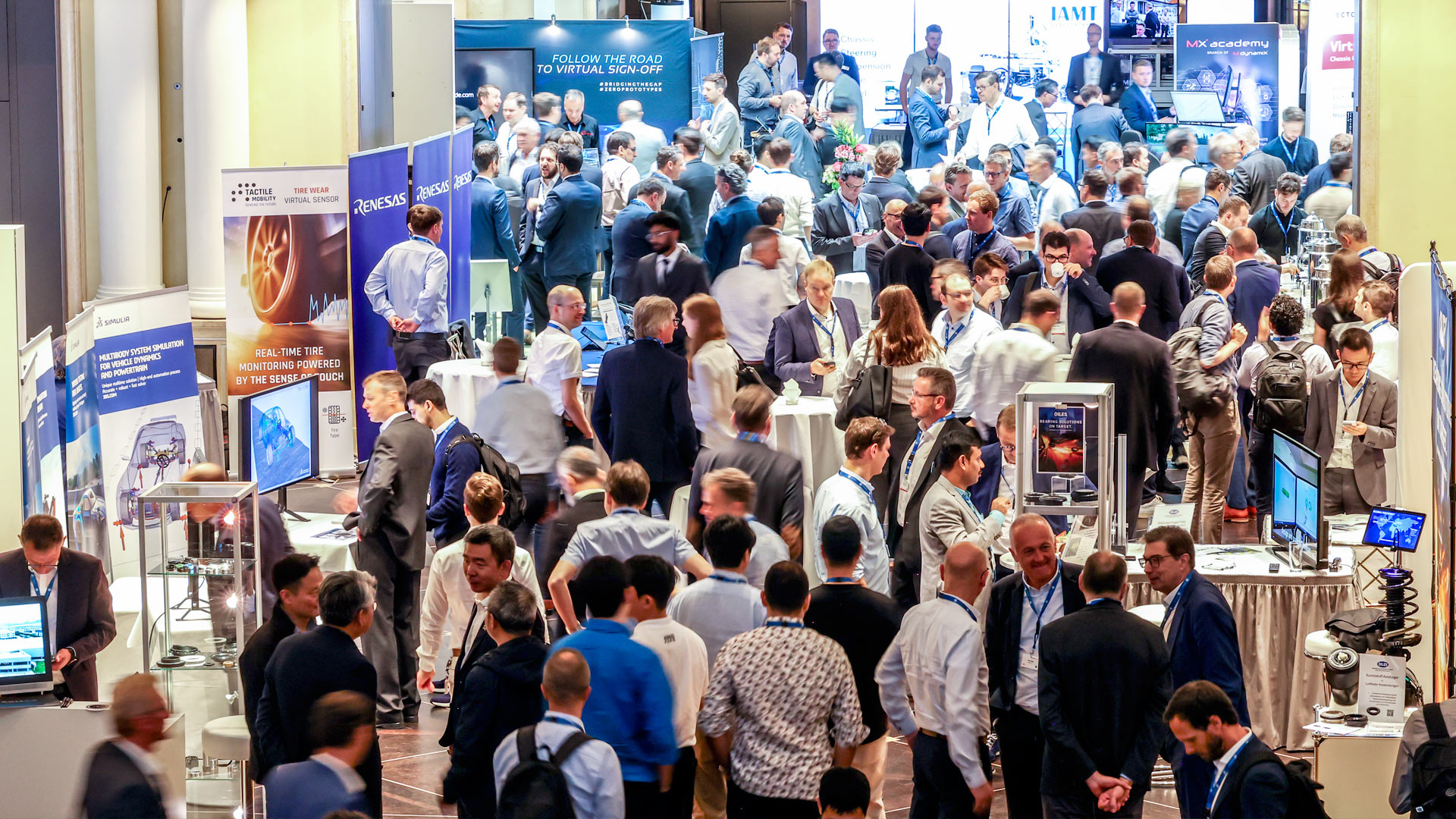

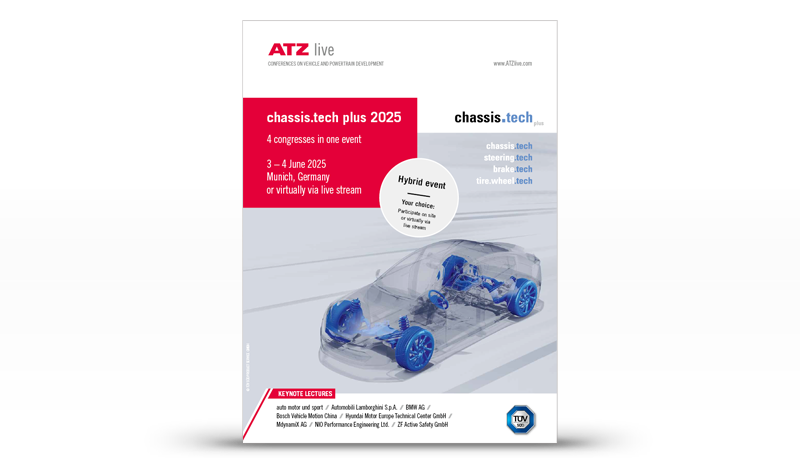

chassis.tech plus 2025

16th International Munich Chassis Symposium | Hybrid Event

4 congresses in one event

03-06-2025 – 04-06-2025 – Munich or virtually via live stream

Main subject areas

chassis.tech plus

Understanding the chassis in the context of its interactions –

Harmonizing chassis development processes with those of automated driving and electric mobility

Adapting the chassis components to the vehicle –

Closer linking of components, modules, and systems for high levels of integration

chassis.tech

Smart chassis systems –

Using software tools, AI, digital twins, virtual testing, and road tests intelligently for optimized vehicle dynamics

steering.tech

Innovative steering systems –

Creating robust and interactive solutions for steering feel, steer-by-wire, hand-over, and take-over

brake.tech

Reliable brake systems –

Representing brake-by-wire, brake blending, pedal feel, and Euro 7 environmental aspects reliably in testing and simulation

tire.wheel.tech

Modern tire and wheel components –

Developing methods and processes for tire/road interaction and for sustainable products

Keynote lectures

Dr. Mihiar Ayoubi

BMW AG

Stéphane Cassar

ZF Active Safety GmbH

Jens Dralle

auto motor und sport

Tyrone Johnson

Hyundai Motor Europe Technical Center GmbH

Prof. Bernhard Schick

MdynamiX AG

Danilo Teobaldi

NIO Performance Engineering Limited

Frank Ueltzhöffer

Bosch Vehicle Motion China

Victor Underberg

Automobili Lamborghini S.p.A.

Authors: Dr. Alexander Heintzel, Michael Reichenbach

News from the 16th International Munich Chassis Symposium chassis.tech plus 2025, Germany

Chassis meets Software

chassis.tech plus inspires with innovations that focus on the connection between chassis and software-defined vehicle. Four keynotes laid the foundation for this.

“The ‘Neue Klasse’ project marks a phase of transformation for us,” explained Mihiar Ayoubi (BMW). “With the new electric drive system, it was possible to completely redesign the architecture. We therefore refer to it as a digital chassis because it is based on an on-board network and is also more and more closely linked to the powertrain.” Now, for the first time, it is possible to pre-control maneuvers, making the actual maneuver significantly faster and smoother. BMW has now succeeded in bringing the powertrain and chassis together. Ayoubi: “With this control structure, we are able to avoid using the mechanical brakes in over 90% of cases.” Ayoubi goes on to say that people always talk about software-defined vehicles, but these are not just made up of software. The quality must first be right in the hands of the customer, and then the software comes into play.

Individually selectable driving experience

“At first glance, feeling and power don't go together, but in our industry, it's all about feelings,” emphasized Tyrone Johnson (Hyundai). “That's why our customers can now determine the feeling they have when driving by choosing their own sound or individual driving experience.” Even noticeable gear changes or misfires can be adjusted virtually.

The European development center HMETC is celebrating its 30th anniversary and is Hyundai's only one in Europe. “We have invested over 150 million euros in the new Square Campus in Rüsselsheim. Over 500 employees work at the site.” Europe is a crucial and important future market for Hyundai, not least because of the large number of manufacturers. The Genesis GV 60 is the best example of the cooperation between Rüsselsheim and Hyundai Korea.

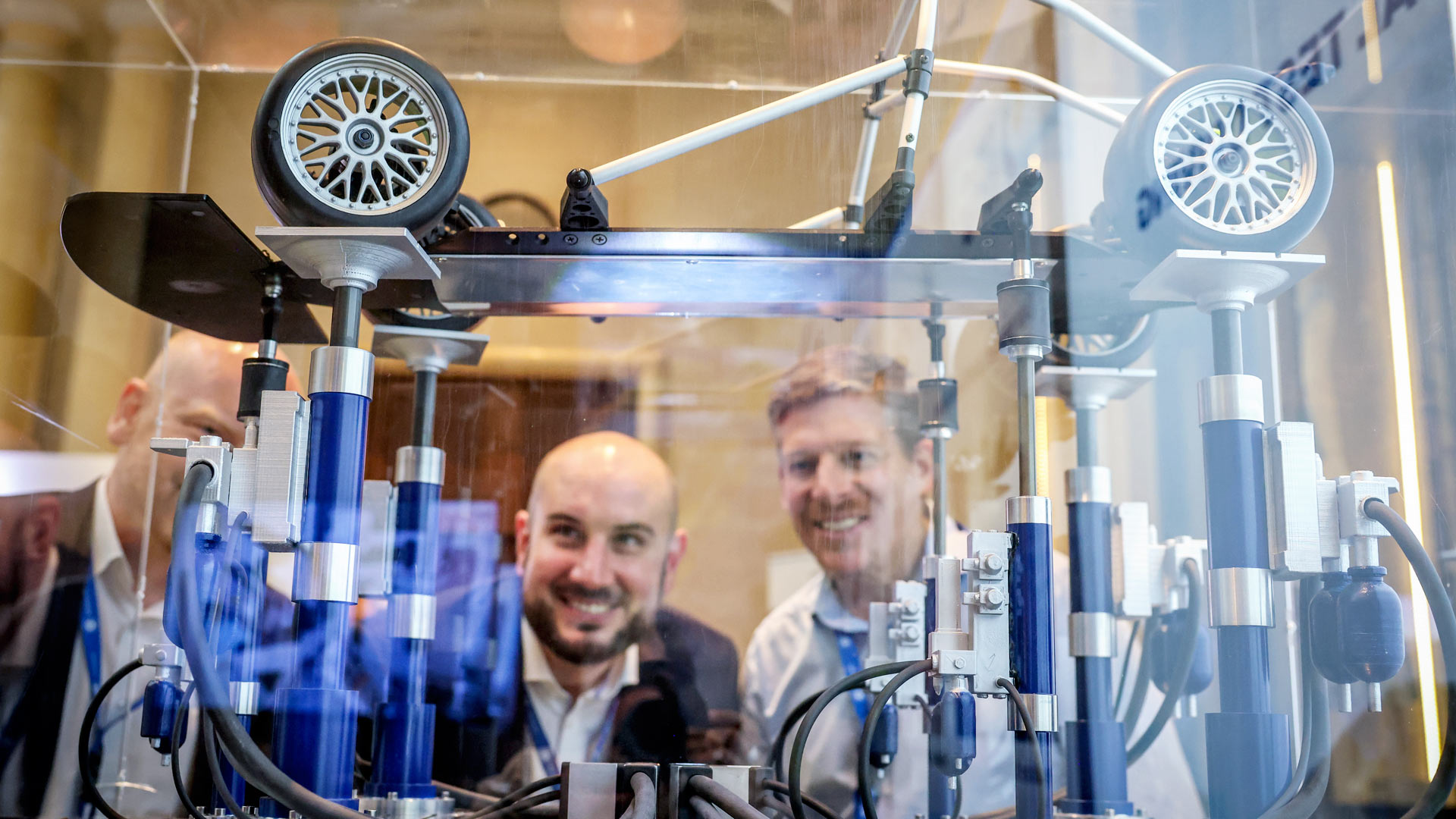

Compact and robust steer-by-wire

“Why steer-by-wire?” asked Danilo Teobaldi (Nio) in the joint keynote speech with Stéphane Cassar (ZF). The steering system in the Nio ET9 is one of the first SbW implementations. “The buzzword,” said Cassar, “was freedom in the development of a car built on a new platform. The result is a software-defined solution that eliminates mechanical lines and cables. This SbW is redundant, compact, and robust.”

According to Nio and ZF, the goals were a variable steering angle in a wide range, precise steering feel, and good road feedback. Cassar: “In addition, high torque density of the actuators is important. The system consists of a double worm gear with torque feedback.”

More intuitive operation required for ADAS

A joint presentation by Jens Dralle (ams) and Bernhard Schick (MdynamiX and Kempten University of Applied Sciences) on “Strengthening ADAS testing experience from a customer perspective” provided interesting insights into how end customers perceive driver assistance systems. “The idea of developing a joint test procedure dates back to 2006 and has now become standard in test criteria for ADAS,” Schick stated. Over 40 customer studies have been completed since 2017, most recently in Brazil with VW, as reported in Evaluation of ADAS Functions and HMI from a Customer's Perspective Using the Example of Brazil in ATZ 4/2025.

“The systems need to be better, more intuitive, and more harmonious, and they need to perform predictable actions,” demanded Dralle. The tests should be repeated every year if possible. The first series of tests was carried out with Mercedes ETS, Tesla Volvo EX30, and Nio ET5 for their ACC systems. Dralle: “All four had problems with stop-and-go traffic and overtaking. Mercedes had the best results in braking maneuvers, Tesla was acceptable, but Nio and Volvo were poor, braking too early or too hard.” None of the four hit the sweet spot. “There is a lot of variation, both subjectively and objectively.”