Register now.

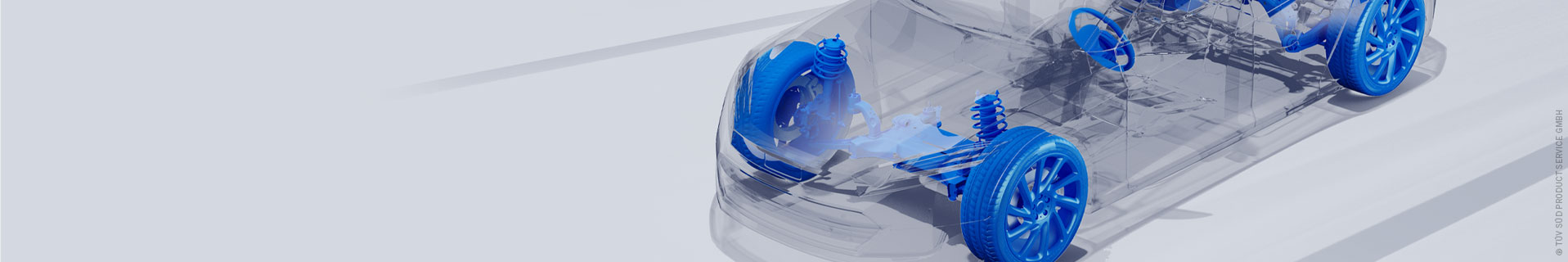

chassis.tech plus 2025

03-06-2025 – 04-06-2025 – Munich, Germany

Cooperation partners

A trade exhibition will be taking place on both conference days. Manufacturers and suppliers of the automotive industry will present the latest developments and interesting services to the specialist audience.