Heavy-Duty Engines 2026

24-11-2026 – 25-11-2026 – Salzburg, Austria

Cooperation partners

An accompanying trade exhibition will be taking place again next to the function rooms on both conference days. In numerous booths, manufacturers and suppliers of the automotive industry will present the latest developments and interesting services to the specialist audience.

Since 1987 Cambustion’s products for engine and after-treatment emissions development have been adopted by customers in over 35 countries globally, including OEMs, Tier 1s and researchers in academia.

Our automotive emissions product range includes transient analysers for both gases and particles, for both real-world and cycle development, and complete testing systems for particulate filters.

Cambustion continue to innovate, offering analysers and techniques to support Euro 7 development, combined with alternative fuel research including biofuels, hydrogen, ammonia and others, which bring special emissions challenges. Cambustion products are also applied to non-engine measurements, including brake particles and cabin air quality.

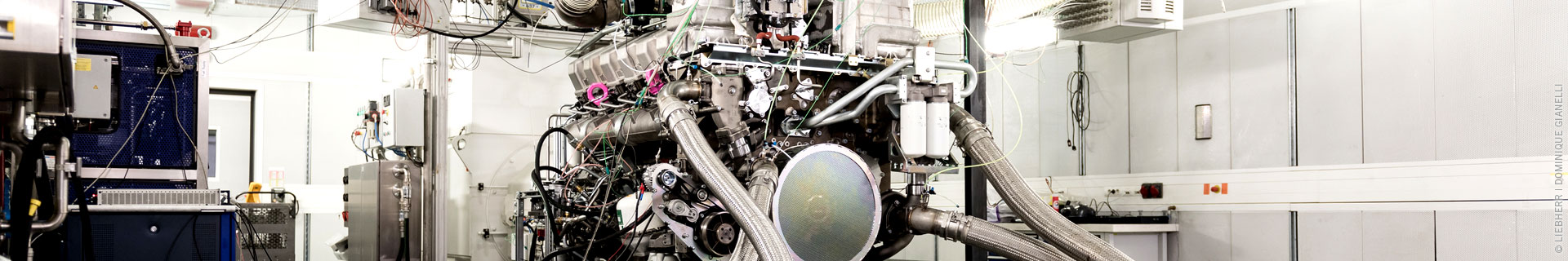

KST – Testing powertrains to move the future

As an independent testing service provider with a strong focus on innovation and more than 55 years of experience in engine and powertrain development, we have established ourselves as one of the key players in this market.

KST offers a full range of specialized testing services for OEMs and Tier 1 suppliers. Our infrastructure boasts close to 85 state-of-the-art engine test benches for passenger and commercial vehicle tests as well as for off-road vehicle test applications with a strong emphasis on development Topics for e-mobility, hydrogen drive systems, and synthetic fuels.

We also bring a high level of experience and competence to the table, in the field of industrial, rail, and marine engine testing with a power capacity of up to 4 MW.

KST’s service portfolio overview:

• Electric / hybrid drive systems in all performance categories

• Power electronics / inverters, including HiL

• Battery testing, including reliability and abuse test work

• Hydrogen-based drive systems, hydrogen engine and fuel cell testing, and electrolyser

• Synthetic fuels / operating materials, including HVO

• Large engines – industrial / railway / marine, including hydrogen applications

• Future-oriented technologies for internal combustion engines

"Springer Professional" is the digital literature platform with technical and other specialist books and journals that are relevant for companies and organisations. More than 3.8 million full-text documents are available for precise research. Each document can be viewed and downloaded in PDF format. Employees in more than 400 companies already use "Springer Professional". They appreciate the huge range of sources and the options to personalise "their" Springer Professional.